“Conventional methods restrict manufacturers to certain conditions, hindering ideas generated from different perspectives. Companies that develop strategic design create solutions for the improvement of the production process and provide an innovative experience for the manufacturer. These companies define and manage the processes which take design to a new level.”

The Impact of Design on Product Dynamics and Development

Design is seen to be a significant development area for shaping a product and giving it an identity. However, there is more to it than that. Today, most of the brands expect a constantly evolving product strategy. In addition to aesthetic values, innovative user experience and transformative technological solutions are the main factors that add value to the design.

The whole product development process from ideation to production should be experienced altogether with the designer, client and manufacturer. Exploring new paths and creating a comprehensive strategy are common responsibilities. Conventional methods often restrict the abilities of the manufacturer and get in the way of innovative ideas. Designers provide innovative experience to the manufacturers by searching solutions to improve the current conditions.

Design Strategy Necessitates a Definite Decision between Two Approaches

1- Adhering to conventional methods and developing a product within the standard understanding.

2- Identifying and managing new processes that will carry the design forward

Conventional methods confine all the actors to certain conditions, thus hampering different perspectives. Innovative solutions are often created during the production process. Action-taking requires deep experience and know-how. The second path is always costly and risky. However, it takes courage to create great opportunities.

Developing a new production method is an adventure, the new method has to become a controlled platform and carefully added to the production process. New production step is created to improve efficiency and sometimes it enhances the physical properties of the design or adds value to the engineering. This process provides an area for development and innovation, and it should be regarded as an opportunity especially by the manufacturer.

“Design process should allow time for generating multiple benefits”

Arman Design values constant search for improvement in all stages of the process. From the start, each project offers opportunities for development, segregation, productivity enhancement and value creation for each stakeholder. The stakeholders receive their share from this area of development as much as they adopt and internalize. Arman Design doesn’t only value a good design, but sustainability, resource management and experience are also very much appreciated.

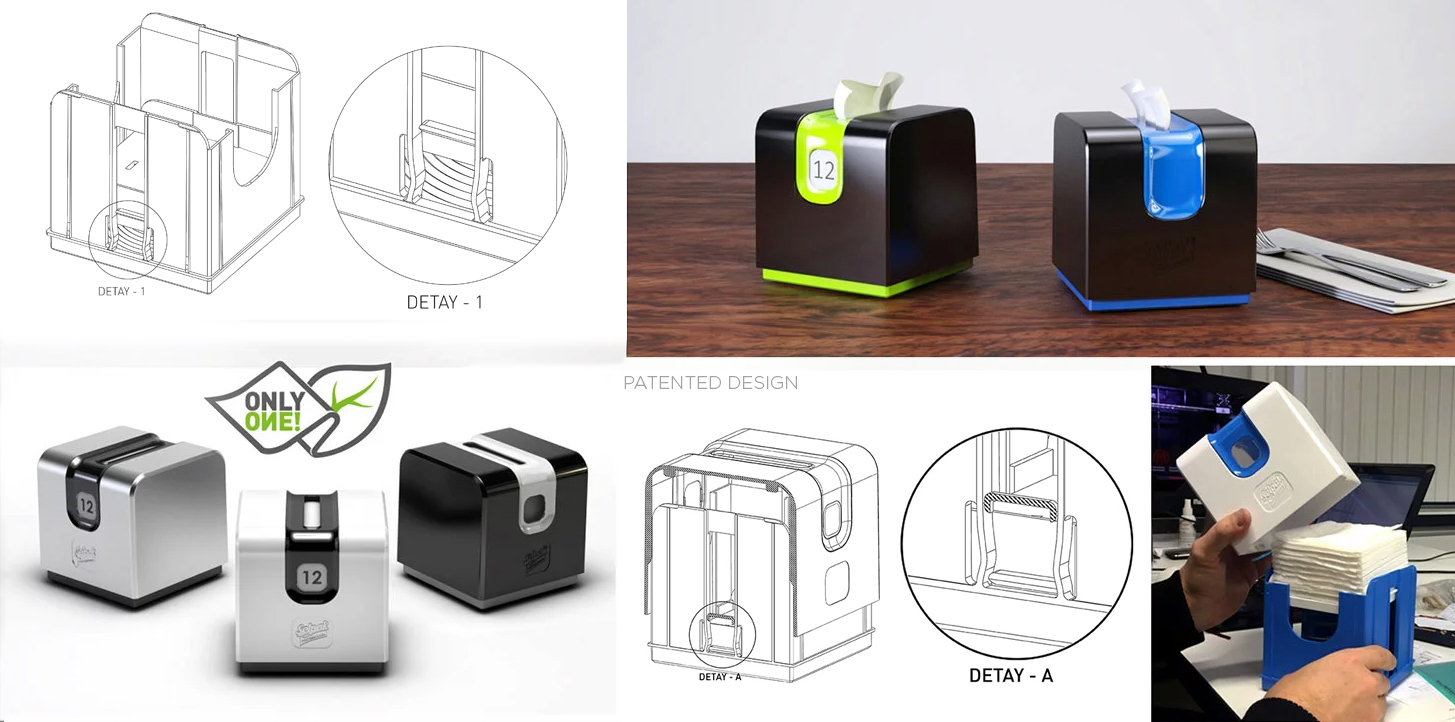

Case Study: Additional Steps to Plastic Production Flow

Electronic devices which have high IP ratings often face problems regarding sealing electronic equipment casing. When plastic casings are produced for these devices, sealing areas are formed by double injection. Double injection in a heavy engineering process and manufacturers who do double injection are quite rare. Usually, the components are made out of plastic and gaskets are assembled by hand.

Arman Design team designed a model to meet the standards in mass production processes. This only became possible by accurately defining the production needs of the client. Arman Design developed a programmable robot for this purpose and positioned it to the manufacturer. A standardized production was carried out with a robot that seals newly manufactured parts using pre-determined materials. Thus, the automat made the production process highly efficient. This robot platform has been designed to create solutions for various products designed in the future.

As a result, development of design principles is only possible when innovative approaches are present. The manufacturing platforms of the suppliers are often not suitable for increasing the value of the design and achieving a high level of performance. Therefore, various interventions are required to increase both the quality control levels and the efficiency of production performance. An added instrument to the production process such as a new machine, vending machine, etc. will directly affect the efficiency of the production process and the quality of the product.

Arman Design carries its own design identity one step at a time and provides its customers with a high value-added and marketable products.

Written by Murat Armağan

Primitive Use of Artificial Intelligence: A Look from Past to Present

Primitive Use of Artificial Intelligence: A Look from Past to Present  The Future of Medical Design

The Future of Medical Design  A Night Full of Prizes: Celebrating 4 Wins at iF Design Awards 2023

A Night Full of Prizes: Celebrating 4 Wins at iF Design Awards 2023