Companies are usually unaware of the massive decision-making process required for manufacturing a product. Even in a simple example of bringing two housings together, there are options of gluing, ultrasonic welding, screwing, snapping, or attaching with extra part. We collaborate with the manufacturers earlier in the design process in order to successfully carry out ideal production strategies.

PRODUCT &

PRODUCTION

STRATEGIES

Production strategy,

refers to a long-term action plan, applied for achieving the organizations key goals. The strategic decisions include many aspects like the appropriate investment, production technology, training of the production staff, the schedule to follow etc.

As for product strategy,

decisions start from determining what to produce, up until when to introduce to the market. There are many possible ways to go such as differentiation, cost-leadership, market segmentation, quality, flexibility, eco-friendliness, and so on.

Case Study : Armon V10

Armon V10 is a multi-factor access control reader, combining 5 different technologies. Our client required a product that responds to changing customer needs in the developing culture. Our research defined that along with a stylish look, the product had to have flexibility. Being adjustable to different needs was actually essential for our client’s business model.

We built our product strategy upon variability. The productconsists of multiple components that can create a family of 8 distinct products through different assembly options, or can contain them all at once. This allowsspecialization for different environments and needs, without any extra costs.

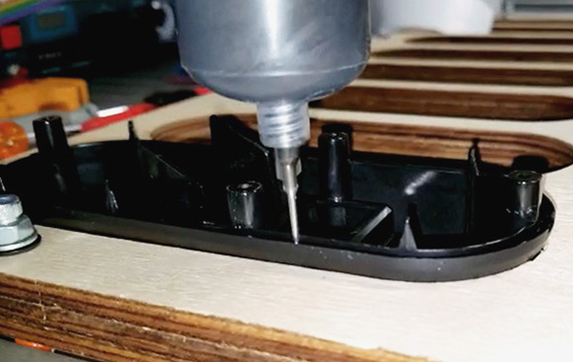

During production phase, at one point we built our own machine and material as a cost-effective and specialized solution. We innovated upon an existing technology so that we can automate a group of manual labor processes. Once we were able to do sealing and gluing for curved parts, our design and manufacturing barriers were removed. Injection material was also developed with our collaborating chemists to specifically address our needs. Something that is quite rare and costly was now available to us for this project and other projects at hand as well.

With a well-planned product and production strategy, we exceeded our client’s initial expectations. The product received very positive feedback from the field testing even during the prototype phase. We successfully fulfilled our goals within the decided duration.

Prototyping & Testing

Ideas can be powerful and quite motivating, but alone, they are only hypotheses. So following the ideation phase in design process, comes the testing of ideas. We create rapid prototypes and run pilots to receive valuable user feedback. This allows us to learn fast and iterate in loops until the perfect user experience is reached.

In defining an efficient roadmap to production, we make sure to test our ideas with prototypes in early stages to prevent costly complications to occur later.

Prior to making physical models, we run simulations on CAM software for analyzing right materials and design for parts. This ability reduces the time and money spent on resolving basic issues. Then we build to learn.

We inspect wall thicknesses, examine parts to be molded, try to foresee potential part defects, and plan the assembly; all with durability and quality in mind. These aspects determine a reliable roadmap and timeline for delivery.

Case Study: Talking Hands

Talking Hands is a set of wearables that translate sign language into speech. When our client came with the project, the technology was not yet defined. So we joined in the R&D process, incorporating appropriate technologies. Since there were no definedproduction processes, we ran studies for developing methods. We came up with a method that merges thermoplastic and textile along with water and impact resistance.

We introduced production parameters to manufacturers and assembled a small batch production for user tests. The initial goals were reached. But we didn’t stop there as this is an ongoing R&D project.

Ergonomic studies were run with different people & hand sizes.We now continue to develop the process, working on gloves that can be printed for individual hand sizes, using our in-house built machine. We keep working on new ways to improve the technology, quality, and the user experience.

Inventing Efficient New Ways for Better Execution

A good product and production strategy can significantly increase your business potential to succeed.

In every project we push the boundaries of materials and manufacturers further. We search new ways to enhance product quality, create faster output, extend product life, simplify assembly, and decrease costs. At times we even invent new production techniques and materials for better solutions.

We innovate at all stages, from the initial concept to the moment the product leaves the factory.

For us, an idea is only as good as its execution.

Ready to invest in design yet?