Speed and Precision Through Digital Tools

Industrial design processes no longer take shape solely at the drawing board — they now evolve in digital environments. Thanks to CAD modeling, simulation, digital twin technology, and rapid prototyping methods, a product’s performance can be almost entirely tested before production begins.

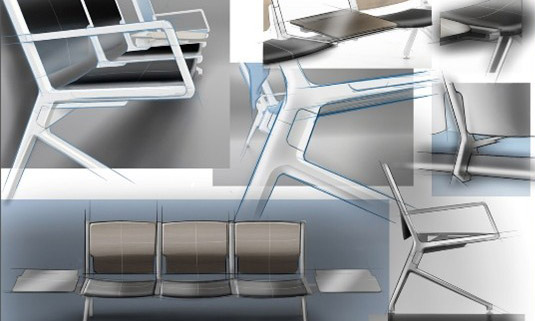

These technologies not only accelerate the process but also make it possible to unite engineering accuracy with aesthetic vision. How a product will be manufactured, the tolerances it will operate within, and the environmental conditions it will withstand can now be predicted in the early stages of design. This approach transforms design from

a process of trial and error into one based on foresight and analysis.

Value Beyond Aesthetics

The power of design lies not only in appealing to the eye but in being durable, manufacturable, and user-friendly.

“Is this product merely beautiful — or is it intelligently designed?”

The engineering intelligence behind aesthetic lines defines the true value of a product. That’s why we see every design not merely as a form, but as a system of solutions. Material choices, assembly methods, durability, and ergonomics form the unseen layers of design that shape user experience. Ultimately, the resulting product becomes a harmonious whole — balanced between aesthetics, function, and production.

From TRT Documentary to Modern Design Philosophy: The Anatomy of Industrial Innovation with Arman Design

From TRT Documentary to Modern Design Philosophy: The Anatomy of Industrial Innovation with Arman Design  The Future of Industrial Design in Turkey

The Future of Industrial Design in Turkey  Design + Engineering: More Than Aesthetics

Design + Engineering: More Than Aesthetics